MaNuK -

Magnetisable slot-locking wedges consistently thought through!

The material and production expertise of M&D Composites Technology GmbH helps to make heavy things light, but it also helps to make electrical machines more efficient and smoother-running. The MaNuK development project will make a new generation of magnetisable slot lock wedges available. The development project is funded by the Federal Ministry for Economic Affairs and Climate Protection (BMWK) via the Central Innovation Programme for SMEs (ZIM).

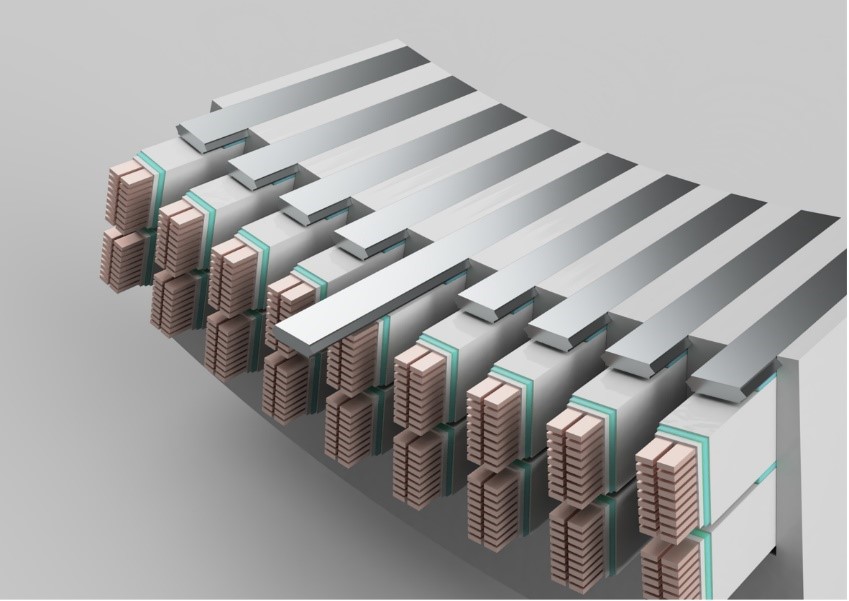

Slot locking wedges are used in electrical machines with open slots in the laminated core to fix and protect the winding. The wide slot openings in the laminated core, which increase the magnetically effective air gap between the stator and rotor, cause an undesirable local weakening of the magnetic field. Magnetic slot closure wedges counteract this by improving flux guidance. The main result is a reduction in the required magnetising current and consequently a better power factor as well as an increase in the efficiency and smooth running of the electric machine.

The magnetic slot lock keys (mNVK) available today have considerable potential for improvement in terms of their magnetic performance and mechanical properties - premature failure is often the cause of system damage and downtime.

The specialist for lightweight components M&D Composites Technology GmbH from East Frisia, whose initiative initiated this development project, aims to improve the technical properties of magnetic slot locking wedges (mNVK) and significantly reduce unit costs by utilising continuous production processes, making them particularly attractive for electrical machine manufacturers. ‘Until now, our focus has not necessarily been on applications in the field of electrical machines or in the field of electrical insulation in general,’ says Gregor Müller, Managing Director of M&D Composites Technology GmbH, ‘this shows how expertise from classic lightweight construction can also be utilised for applications in the field of electrical machines. The market as a whole is of a very interesting size and is attractive enough for us to offer special solutions and gain a foothold in this application area.’

The MaNuK project is a co-operation project between the partners M&D Composites Technology GmbH, Schill & Seilacher ‘Struktol’ GmbH, FISCO GmbH, the Institute for Drive Systems and Power Electronics (IAL) at Leibniz Universität Hannover and the Institute for Polymer Materials and Plastics Technology (PuK) at Clausthal University of Technology.

The main objectives of the research project are as follows.

In order to optimise the magnetic properties, the focus is on producing a targeted flux guide, testing the magnetisation requirement/power factor and determining the efficiency. Measurements of test specimens are used to formulate dimensioning guidelines and rules as well as analytical functions to describe the permeability. ‘We at the Institute of Drive Technology and Power Electronics at LU Hannover (IAL) can use calculation tools to calculate and visualise corresponding example machines based on conventional and the new type of mNVK,’ says Martin Gerlach, who will be supporting the project on behalf of the IAL. Not only does the continuous production process that will be used require customised resins, but new ferritic components will also be necessary to make the planned processing possible. To this end, the consortium will draw on the many years of experience of Schill & Seillacher - Struktol.

Another development goal is to improve strength, with a particular focus on analysing fatigue strength and service life as well as increasing reliability. ‘PuK's research focuses on the interrelationships between filler conditioning, the structure of the magnetic slot lock wedge and its magnetic properties, which form the basis for the new structural design of the slot lock wedge and the development of a new, continuous and significantly more economical and resource-efficient manufacturing process to eliminate the previous disadvantages,’ says Hendrik Detampel, who will be working intensively on this task for the Institute of Polymer Materials and Plastics Technology (PuK) at Clausthal University of Technology.

The development goal of a continuous and significantly more cost- and resource-efficient production process is essential for the future economic success of the new mNVK.

In FISCO GmbH, a development partner has been found for the MaNuK research project that has already successfully demonstrated its ability to realise continuous production solutions for highly filled resins with highly abrasive solids in connection with other products and applications.

The consortium of the research project MaNuK - ‘Magnetic slot closure wedges in continuous production processes’ officially started its work on 24 February as part of a kick-off event. The project is scheduled to be completed by the end of 2023.

Interested producers and manufacturers of electrical machines are welcome to contact the project manager Axel Rademann, M&D Composites Technology GmbH in Friedeburg, at any time to discuss the basic technical requirements for mNVK.