Balancing work and family life....

... we were recently invited to take part in a lecture event with young students to discuss the challenges of setting up companies and developing them into successfully operating organisations.

It was fun to pass on experiences and talk about opportunities, risks and both good and bad decisions in this context.

In this context, the question of what contribution the compatibility of work and family can make to the success of a company came as no surprise.

In our opinion, it is a real asset for every company to create the conditions and specific offers for this: After all, workforces are becoming increasingly diverse and so the needs of individual employees are also very different, especially when it comes to balancing work and family life.

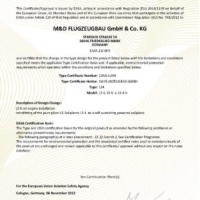

In our companies M&D Flugzeugbau GmbH & Co. KG and M&D Composite Technology GmbH, these requirements and programmes are in place.

✅ Hybrid working according to desire and need and not according to quota

✅ Ability to work flexibly in production

✅ Free emergency childcare if your own childcare is cancelled at short notice

✅ Permission and possibility to bring children to the company

✅ Our wage and salary model, supplemented by a qualification matrix, forms the basis of our promotion policy, which gives equal consideration to all genders

If there are other good solutions, I would like to learn about them and look forward to your feedback in the comments!

Greetings GMU